Chute Wear Liners

![]()

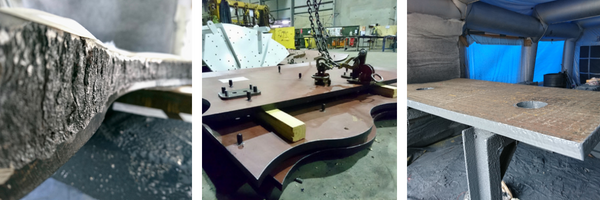

Large in size and weight, these 2-tonne wear plates line a massive iron ore chute at the Yandi BHP mine site in the Pilbara, WA.

Large in size and weight, these 2-tonne wear plates line a massive iron ore chute at the Yandi BHP mine site in the Pilbara, WA.

Australian Resin Coatings was engaged by Enduraclad International to provide a protective coating for the tungsten wear plates to protect the edges from chipping on installation – this proved successful

An ongoing trial, which is forecast to be carried out over the next five years, is to ascertain the suitability and durability of RhinoChem 2170 polyurethane and its ability to lengthen the life of the liners and help stop the ore from chipping the wear liners out from the edges.

Application Process

The surface area of the wear plates was prepared and primed with RhinoPrime 251. Depending on the depth of the wear plate edge, 3-8mm of RhinoChem 2170 was applied to provide an extremely durable, abrasion and impact resistant surface.

Work completed by Global Coating Systems