Rhino Sprayed on Polyurethane Protection for Hi-Rail Truck

![]()

Hi-Rail Trucks – Rail Maintenance Vehicles

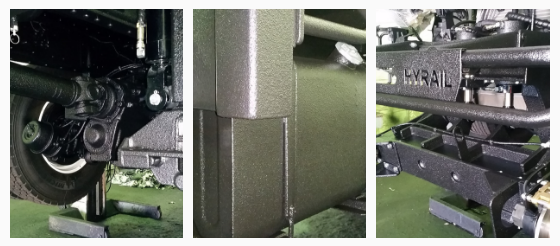

Built for FMG Mining, this Isuzu truck is fitted with a Hi-Rail system which means it has Train Wheels and drive system on the front and rear and therefore can travel on the clients rail line. The truck can drive on regular roads using its rubber wheels. When it gets to a rail line, it straddles the rail line, and the Hi-Rail units fold down lifting the truck off its rubber wheels.

The role of this vehicle is to carry equipment along the rail line and perform track maintenance.

Now the question is why did they go to all the trouble of coating the entire underbody, chassis, diffs, Hi-Rail unit, diesel and air tanks?

Well, the answer is simple – Most of the roads this truck travels on to, and from, the rail line are mainly gravel which is sprayed with water 24hrs a day for dust suppression. It is a waste to use good clean drinking water so they often use second grade reclaimed water from dams or the ocean and it is very salty.

Salt Water + Dirt + Chipped Paint = RUST !

…and very quickly it will rust – this truck is worth about $500,000 so they would like it to last up to 10 years.

So from both a cost saving and ease of application perspective we use a combination of High Build Industrial Epoxy and Rhino Linings polyurethane coating system.

First, everything is sprayed with a 300µm DFT coating of our High Build black Epoxy (known as Beamastic). This product also provides an excellent primer or base for the Rhino product.

Then we simply spray Rhino Duraspray on anything we think will cop the flying debris. This is typically the chassis rails near the rear wheels, the fuel and auxiliary tanks that stick out the side, both diffs, and in this case, the Hi-Rail units mainly because they are very expensive and the client wanted the added insurance of the double coating (Epoxy and Rhino)

Work completed by Beam Rustproofing located in Belmont WA.

For further information contact Beam on (08) 9325 1399.