Mining Trucks – Heavy Vehicle Protection

![]()

Rhino Linings provides heavy vehicle protection

Large mining trucks are the cornerstone of the mining industry, moving material such as coal, sand, rock and ore. They are built tough for the terrain they work in, but sometimes some added protection is required due to the highly corrosive environment that exists on a mine site. Following are three case studies of work completed by Rhino Linings of Singleton, NSW Australia.

Cab of Komatsu Haulcab

This Komatsu 830e 240 ton Haulcab cab is part of a Rio Tinto fleet used in the highly corrosive environment that exists on a mine site. The cab had started to corrode and the client was concerned the existing floor matting did not meet their slip resistant requirements. In addition, as the mats were only partially bolted down, dirt and moisture was being trapped underneath causing corrosion to the cab floor. The moisture was also creating an odour in the cab.

The cab was first sandblasted and repaired prior to application of Rhino Prime 251 and Rhino TUFF STUFF. Slip resistant particles were also applied to finish off the application. The company was very happy with the cab and intends, over the coming months, to have the same work carried out on the balance of their fleet of Komatsu dump trucks.

Caterpillar 793 Haul Truck Fuel Tanks

This Caterpillar 793 Haul Truck is part of a fleet used in the extreme corrosive environment that exists on mine sites.

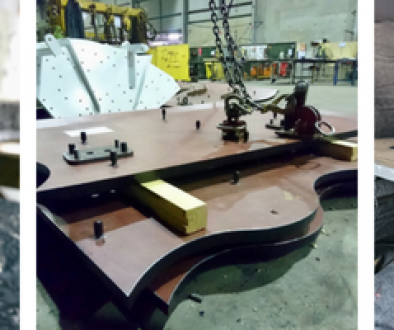

The 5,000 ltr fuel tanks of these Caterpillar 793 Haul trucks, located directly behind the front wheel, acts as a mudguard and are extremely vulnerable to impact and of course corrosion. In order to obtain a much longer service life the client required the fuel tanks to have as much impact and corrosion resistance as possible.

Due to the weight of these tanks, the work including having the tank suspended by a crane in order to prepare the area prior to the application of Rhino TUFF STUFF® . Upon completion, the entire tank was then painted in Caterpillar yellow.

The extremely fast cure time of Rhino TUFF STUFF®, allows for easy application to vertical and overhead surfaces. The clients intend to have further fuel tanks sprayed as they are removed for inspection.

Caterpillar 798 Haul Truck Mud Guards

Rhino Linings products are utilised in many areas on mine sites, including bunds, machinery, flooring, conveyor belt maintenance in addition to heavy vehicle protection for corrosion and impact.

The mud guard of a Caterpillar 798 Haul Truck is situated directly over the front left hand wheel, it is therefore extremely vulnerable to impact and corrosion. Rhino Linings TUFF STUFF was used in this area for its corrosion and impact protection properties. In addition the battery box and door were also sprayed to prevent the battery from shorting out on the metal surface should it become dislodged from its mounting.

The first guard has been in operation for over 18 months and is showing no signs of wear. Since the initial trial a further 3 guards have been sprayed.

Rhino Linings spray applied products continue to provide the same protection for large vehicles such as these and other industrial mining applications on mine sites throughout Australia and Internationally.

Contact Rhino Linings Head Office today on +61 7 5585 7000 and talk to our team of highly trained technicians. Our Technical team have worked on major projects all over the world and have industry leading experience in the correct use of our application equipment and lining systems.