Rhino Linings Protective Coatings Blog

![]()

-

Press Release – Testing Battlejacket® with the Australian Army BattleJacket® coatings proves the ultimate self-sealing under fire: Withstands .50cal machine

-

Lining Wastewater Treatment Plant Tanks – Australia Protective coatings for wastewater treatment plant tanks Category: Chemical Resistant Tanks Project: Protection from

-

Protecting the Underside of Crop Dusting Planes Protective coatings for crop dusting planes Category: Abrasion Project: Underside of Crop Dusting

-

Road Train Side Dumpers Prevent hangup and wear on your side dumpers! Category: Abrasion Resistance & Corrosion Protection Project: Side

-

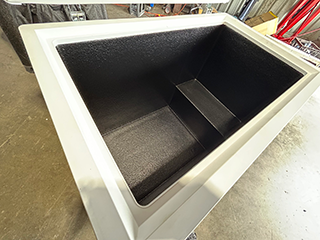

Converting Chest Freezers into Ice Baths Economical Freezer to Ice Bath Conversions Category: Waterproofing & Re-enforcement Project: Converting Chest Freezers

-

Corrosion & Abrasion Solution for Aggregate Hoppers Get more life out of your Hoppers! Category: Corrosion & Abrasion Resistance Project:

-

Protecting Off-Shore Oil Rigs from Corrosion Protect your assets with corrosion proof Rhino Linings coatings! Category: Corrosion Control Project: Coat

-

Waterproofing the Roof of Springvale Mausoleum Get those roof leaks fixed once and for all! Client: Springvale Mausoleum The Waterproofing

-

BattleJacket™ Containment Systems Protective coatings for the Defence industry Abstract: An urgent requirement existed for the Army to prevent and/or

-

Corrosion-Free Water Storage Tanks How to get more life out of your water storage tanks! Corrosion is an inevitable phenomenon

-

Two More Apartment Building Roofs Waterproofed How to make sure your roof is waterproofed the right way! Two new Apartment

-

Feed Lots Made Easier to Clean Feed Lots / Troughs Everyone Needs Easy to Clean Feed Lots! The rural community

Press Release – Testing Battlejacket® with the Australian Army

![]()

BattleJacket® coatings proves the ultimate self-sealing under fire: Withstands .50cal machine gun test by the Army’s 10th Light Horse regiment.

Lancelin, Western Australia – In a groundbreaking test for Australia conducted on October 20, 2023, a fuel tank coated with BattleJacket®, the revolutionary protective coating, withstood a shower of .50 calibre machine gun bullets without leakage. This remarkable achievement was witnessed in a live-fire demonstration by the Army’s prestigious 10th Light Horse Regiment, proving for the first time down under in person.

Battle-proven for nearly two decades throughout the U.S. military, BattleJacket® is a revolutionary self-sealing, self-healing fire protective urethane polymer coating used to protect vehicles, fuel cells, holding tanks, pipelines, rail-cars, and countless other assets.

BattleJacket®, was applied to a standard 1000l IBC pod, which was then subjected to 27 rounds of .50 calibre machine gun fire. The result was a resounding success, with the reactive chemistry inside the layering technology that uses the fuel as a catalyst to heal the bullet strikes.

High Impact Technologies (HIT), the innovators behind BattleJacket®, are “thrilled with the results of the test,” said Russ Monk. “Our goal has always been to ensure the utmost safety and security for our clients, and this demonstration proves the extraordinary capability of our product. It’s a testament to the hard work and innovation of our dedicated research and development team, now over 2 decades battle proven.”

The implications of this successful test are vast, ranging from military vehicles and infrastructure to civilian applications such as fuel storage and transportation in Australasia. For industries that rely heavily on the integrity of their fuel storage, this could mean a significant reduction in the risk of environmental damage and potential cost savings on repairs and maintenance.

“We’re proud to have partnered with the 10th Light Horse Regiment for this demonstration,”added Kim Boschman. “Their expertise and professionalism were paramount in executing this test and we look forward to potential future collaborations.”

Key Features of BattleJacket®:

• Prevents fuel loss caused by IEDs, mines, and small arms fire

• Field repair patch kit available for larger puncture areas

• Provides vibration and acoustic damping

• Thermal insulation

• Adds structural integrity

• Applicable to both metal and plastic surfaces

• Provides superior corrosion and abrasion protection

• Tenacious adhesion for long-term service

• Available in various colours

• Self-sealing polymer

About Global Coating Systems (Ballistic Industries)

Ballistic Industries is the Military arm of Global Coating Systems (GCS) which specialises in servicing the defence sector with a variety of high-performance coatings; offering blast mitigation, ballistic damage minimisation and prevention and extreme heat exposure damage prevention.

You can download the Battlejacket® Press Release here.

Find out more Battlejacket® information and other protective coatings for Defence here or call +61 7 5585 7000.